10 Easy Facts About American Plastics Shown

Wiki Article

Our American Plastics Diaries

Table of ContentsThe Basic Principles Of American Plastics The Ultimate Guide To American PlasticsThe Best Strategy To Use For American PlasticsAmerican Plastics Things To Know Before You Get ThisFacts About American Plastics Revealed

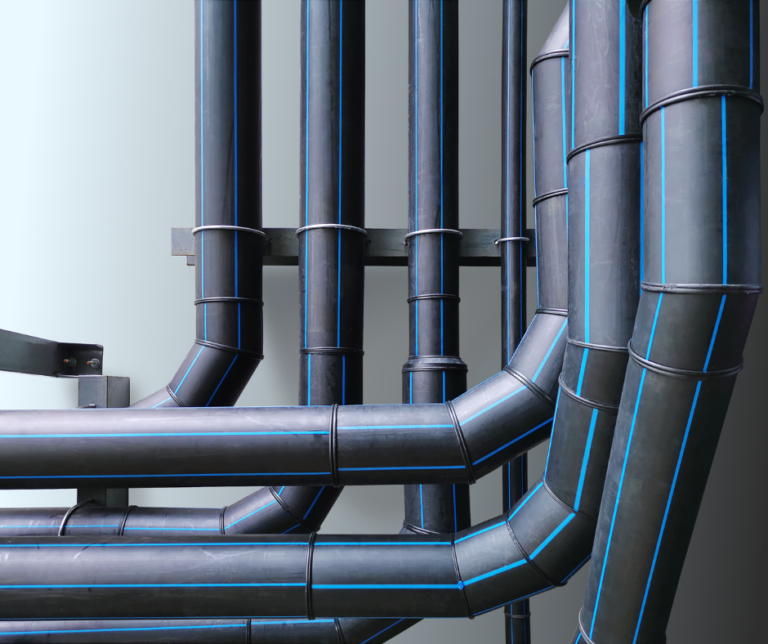

Recognizing these factors will certainly allow you to make educated choices when selecting the most appropriate pipe for your project. The product composition of the HDPE pipeline plays an important function in determining its PSI rating. HDPE pipelines are made from high-density polyethylene, a polycarbonate recognized for its strength and longevity.Various qualities of HDPE may have varying PSI scores, so it is necessary to think about the product composition when selecting a pipe for your details needs. The size of the HDPE pipeline is an additional important factor that influences its PSI score. Bigger diameter pipes generally have greater PSI scores, as they have extra material and surface location to stand up to stress.

The wall surface thickness of an HDPE pipe additionally affects its PSI ranking. Thicker walls supply boosted strength and resistance to pressure, allowing the pipe to manage higher PSI degrees.

It is important to think about the optimum operating temperature level of the pipeline and pick a PSI ranking that can take care of the expected temperature level range - https://www.storeboard.com/americanplastics. The PSI ranking of HDPE pipelines is figured out with rigorous screening and accreditation procedures. Comprehending just how these ratings are determined will provide you with self-confidence in the precision and dependability of the selected pipeline

The Single Strategy To Use For American Plastics

Organizations such as the American Culture for Testing and Materials (ASTM) and the International Company for Standardization (ISO) have established details examinations to examine the performance and stamina of HDPE pipelines. These tests procedure elements such as ruptured pressure, tensile stamina, and long-lasting hydrostatic strength to establish the suitable PSI rating.The stress at which the pipeline ruptureds identifies its optimum PSI ranking, showing the stress it can endure without failure. Long-lasting hydrostatic toughness screening reviews the pipe's ability to stand up to stress over a prolonged period.

HDPE pipelines find with greater PSI rankings are inherently a lot more sturdy and immune to deformation under stress. hdpe pipe fittings Midland TX. Choosing pipelines with greater scores ensures they can stand up to unanticipated stress surges or outside loads, lowering the danger of pipe failing and the need for constant replacements. HDPE pipelines with higher PSI ratings often have enhanced resistance to ecological aspects such as UV radiation, chemicals, and abrasion

Unknown Facts About American Plastics

By choosing HDPE pipes with greater PSI scores, you can make certain the safety of your system and personnel. These pipelines are developed to handle high-pressure circumstances, reducing the threat of leakages, ruptureds, and other harmful events that could endanger individuals or residential or commercial property. Buying HDPE pipelines with greater PSI rankings might need a higher ahead of time cost, however it uses long-lasting cost financial savings.

These pipes make sure the secure and effective circulation of safe and clean water from the resource to the customer. HDPE pipes with appropriate PSI ratings are commonly utilized in gas distribution networks. They can securely deliver gas or various other gases from the source to domestic, business, and enterprise zones, guaranteeing trusted and reliable gas supply.

American Plastics Things To Know Before You Buy

They can take care of the stress needed for reliable watering and watering of lawns, yards, parks, and sporting activities areas (hdpe pipe suppliers Midland TX). HDPE pipes with high PSI rankings are perfect for transporting various industrial chemicals. They can handle the stress needs and withstand chemical rust, guaranteeing the safe and effective transport of chemicals in industrial settings

Proper installation is essential to make best use of the efficiency and long life of HDPE pipelines. Follow these guidelines when mounting HDPE pipelines with particular PSI scores.

Select the proper jointing approach based on the PSI score of the HDPE pipe. custom hdpe pipe manufacturing Midland TX. Usual jointing techniques consist of butt blend, electrofusion, and mechanical couplings. Comply with manufacturer guidelines and make certain appropriate alignment and welding for a secure and leak-free joint. Select installations and devices that are compatible with the PSI rating of the HDPE pipeline.

The smart Trick of American Plastics That Nobody is Talking About

After installation, do stress screening to ensure the honesty of the HDPE pipeline system. Comply with sector requirements and guidelines to conduct the suitable pressure tests, such as hydrostatic or pneumatic testing, to confirm the system's capacity to take care of the needed stress. Proper backfilling and compaction around the set up HDPE pipes are important to offer security and safeguard the pipes from exterior lots.Report this wiki page